- Overview

- Product Description

- Machine working process

- Machine list

- Detailed Photos

- Product Parameters

- Auxiliary machines

- Company Profile

- After Sales Service

Basic Info.

Product Description

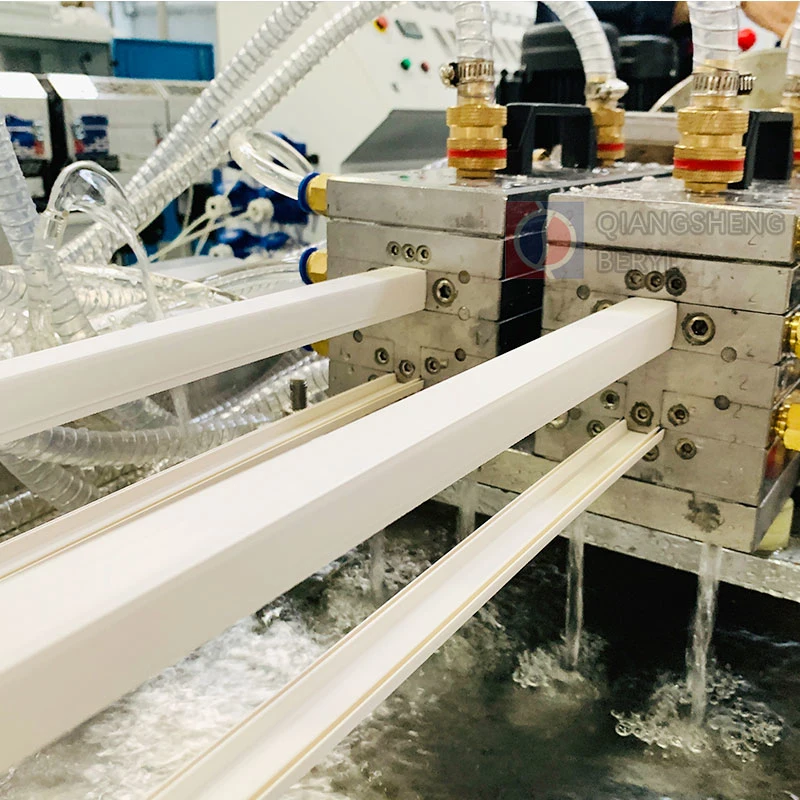

1. Wall cord covers trunking and conduit machine is applied to produce U channel profile which used as PVC electrical cable trunking/cable duct.

2. Wall cord covers trunking and conduit machine is composed of conical twin-screw extruder, vacuum calibration table, haul-off, cutter and stacker.

3.Change different extruding mould,this Wall cord covers trunking and conduit machine can also produce PVC door & window profiles, foamed special shaped materials

profiles, decoration plate material, profile and multi-hole wire plastic products, etc

Application for Wall cord covers trunking :

1. Self-fire extinguishing, non-flammable.

2. It is inpenetrable by insects and termites, and won't rot or rust.

3. Resistance to weather/ special chemicals, waterproof/washable.

4. The excellent rigid and superior impacted surface is without any peeling.

5. Natural wood grain: showing authentic wood srtucture and artistic sense.

6. Easy to be cut, drilled, nailed, sawet, and riveted. DIY is all right.

7. Quick maintenance and no need of painting.

8. The simple and fast installation can save a lot of time and manpower cost.

Raw material +PVC resin + additive → mixing → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & packing

| Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens, Scheider, ABB etc; • High torque gearbox with adopts NSK bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material • Complete set include extrusion die head, calibrator and cooling tank • Adopt to single, co-extrusion, foam imitation marble profile |

| Calibration table | • Include full set of vacuum and water pump • Width: 240mm • Length: 6000mm • Independent operation panel for easy operation |

| Haul off | • Upper/lower caterpilla driven separately and speed control by inverter • Fast change type pads for easy operation • Install plate is adopts aluminum material |

| Cutter | • Lifting saw cutter with adopts double station dust collection system •Synchronous drivingby air cylinder or servo motor control |

| Stacker | • Stainless steel304 as touching material • Discharge driving by air cylinder |

Plastic extruder

1.World famous brand electrical component such as Siemens, ABB etc .

2.High torque gearbox with adopts NSKF bearing;

3.Bimetallic screw and barrel;

4.Intelligent PLC controlling system with human-friendly interface. Mould

Mould

1.Material of mold body is Steel 45# ,harden treated and polished.

2.Material of inner mould parts is 40Cr.

3.The material of calibration bushing is Stannum bronze.

4.The width can be customized.

Vaccum calibration table:

1.Calibrating the pipe outer diameter and cooling pipe.

material of water tank is stainless steel 304.

Hauling off machine

1.Function :haul off stably and synchronal with extruder speed.

2.Clamping mode is pneumatically.

3.speed adjusting mode is frequency conversion.

cutter machine

1.Function:cut in fixed length.

2.Cutting type:automatic meter counting cutter.

Model | YF120 | YF180 | YF240 | YF300 | YF600 |

Product Max size | 120x50mm | 180x50 mm | 240x100 mm | 300x120 mm | 550x120 mm |

Extruder | SJSZ45/90 | SJSZ51/105 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 |

Capacity | 120 kg/hr | 150 kg/hr | 300 kg/hr | 300 kg/hr | 400 kg/hr |

Production Length | 18 m | 20 m | 24 m | 24 m | 28 m |

Zhangjiagang Qiangsheng Machinery Co., Ltd. is professional with plastic machines . We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email. Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )2. Professionally and patiently introduction,details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.2.Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3.Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all

original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your

airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

you solve the problem, or dispatch worker to your factory. All the symbols on the equipment should be in English. Seller is

responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

ACEMIEN will provide long-term technical guide.